Equipment

The ITL Program has a wide range of equipment available to help you design, prototype, build, and test your engineering project—and a knowledgeable tech staff to guide you along the way! Need assistance? Contact the LaunchPoint, our student-staffed starting point for all your ITL Program questions. If they can't answer your question, they will find a staff engineer or specialist who can.

Electronics

Circuit Design

Design, fabricate, test, and troubleshoot circuits in the Electronics Center and the Electronics Fabrication Center and take your electronics-related project to the next level.

Microcontrollers

Use Arduino Uno and other microcontrollers to process electrical input from sensors and control actuators and lights; an ideal starting point for physical computer projects.

Sensors

Measure and record temperature, force, acceleration, vibration, sound, infrared and UV light, and more—hundreds of sensors are available for your project needs.

Soldering

Practice your soldering and rework skills with a variety of hand tools, and master the application of soldering through hole components and surface mount devices.

Rapid Fabrication

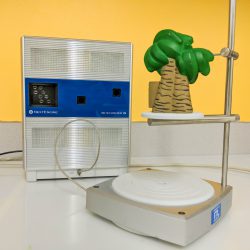

3D Printing

Ready to move your design idea from the drawing board and into your hands? Our 3D printers make your designs a reality through prototyping and into the final stages of your project. Start with the Intro to 3D Printing workshop to begin using our self-service lulzbot 3D printers. For high definition 3D prints on the Objet, Markforged, or Form3 instead request a quote using the form below.

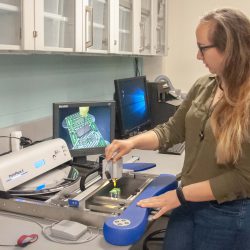

3D Scanning

Who wouldn’t want to create an action figure of themselves? With the help of 3D scanners, you can take real-world objects and digitize them for your modeling needs.

Laser Cutting

The laser machines at the ITLL are ideal for creating a prototype and for quick iterations. The materials suitable for the machines include acrylic, cardboard and thin craft wood.

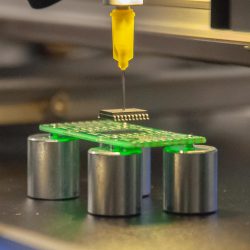

PCB Fabrication

Printed Circuit Board (PCB) Fabrication is the process of designing and machining circuitry. The Electronics Fabrication Center supports rapid prototyping of printed circuit boards.

Shops

Wood Shop

Equipped with the most common woodworking machines and tools, students can master techniques related to saws, drills, and construction for their project needs.

Metal Shop

Access cutting-edge, numerically controlled machines, manual machines, and fabrication resources for all metal, plastic, and composite projects and components.

Data Acquisition Labstations

The ITL Program lab plazas contain data acquisition (DAQ) systems from National Instruments for both high-speed and universal analysis as well as breakout panels attached to DAQ boards.

Material Testing

Analyze material properties and acquire data on structural integrity using instruments designed for tensile, compression, bending, torsion, vibration, and hardness testing.

Computer Information

Computers

A variety of software to assist you in everything from prototyping to design is installed on all public facing computers, many of which are publicly available.

Software

A variety of software to assist you in everything from prototyping to design is installed on all public facing computers, many of which are publicly available.

Laptops

Laptop checkout is available to help keep you on track when you experience computer troubles.

Poster Printing

High-quality, large-format posters priced based on total print size.

We Also Provide...

Modules

Enhance your knowledge through experiential learning through modular experiments, designed to provide hands-on, real-world enhancements to traditional theory courses.

Video Equipment

Cameras, projectors, microphones, and even headphones are available for engineering students and instructors to check out.

Sewing

Not all engineering is done with metal and plastics. Working with textiles is a fantastic way to bring comfort, aesthetic, and versatility to your projects.

Additional Information

3D Printing

Ready to bring your next big idea off the drawing board and into your hands? Our 3D printers are ready to bring your designs through prototyping and into the final stages of your project. Our “Wall Of Awesome” is home to 20 of our Prusa MK4 3D printers that not only allow you to print your parts at your leisure, but also provide the opportunity to gain technical knowledge in the field of additive manufacturing. And when you require a bit more than what these “workhorse printers” can handle, our staff can help you in printing through our high-end 3D printers. These machines--Objet 30 Pro, and Markforged Onyx Pro--are supremely capable, and add a greater selection of materials properties and usage applications to your choices in rapid prototyping.

3D Scanning

Our NextEngine tabletop scanner will help you capture the intricate details of smaller objects, while our handheld Artec EVA Lite scanner is perfect for generating large-scale scans of anything that you can fit through our doors!

Students have scanned bike frames for conducting accurate finite element analysis on digital models, have scanned archaeological artifacts for posterity or non-invasive study, and have even scanned themselves to print mini-figures for gaming! If it’s been made, our 3D scanners are here to help you make it better.

Laser Cutting

The ITLL has five Epilog laser machines available to students, faculty and staff for prototyping. The maximum dimensions that the Epilog Mini machines can support are 18" x 12". The maximum dimensions that the Epilog Fusion Pro can support are 36" x 24". The materials permitted for cutting and engraving are acrylic up to 1/4", cardboard, and craft wood up to 1/8". To gain access to the machines, please attend one of our in-person workshops.

PCB Fabrication

Printed Circuit Board (PCB) Fabrication is the process of designing and machining circuit artwork. The Advanced Electronics Center supports rapid prototyping of printed circuit boards.

The first step to creating any custom PCB is to have transferred circuit schematic design files to a PCB CAM artwork design file (file type will vary depending on the chosen CAD program).

This artwork is transferred to copper clad substrate via milling, chemical or laser etching, and/or laser or photo engraving. The next steps are to drill, plate, coat, and soldermask the patterned copper (where applicable).

The board is now ready for assembly, populating the PCB with components, and testing. A wide range of equipment is available in the ITLL to designers to support each step in the PCB manufacturing and fabrication process, which includes a Reflow Oven, Pick-n-Place, PCB Mill, Electroplater, Etching Tank, soldering stations and various testing/troubleshooting equipment.

Circuit Design

The Electronic Center has the equipment and software to help you design, build, test and repair your electric circuit. Six electronics workbenches provide drop-in workspace for assembly, electrical power, and various instruments and tools, including equipment like that found on the ITLL LabStations. Along with workbenches, the center has the equipment necessary to build permanent circuit boards including a hand drill, etching stations, soldering stations, and a wire rack.

Need a resistor, capacitor, programmable circuit or wire? The Electronics Center also has a variety of small electronics components available for purchase.

Microcontrollers

The ITLL has Arduino Uno and Raspberry Pi kits available for student projects.

The Arduino Uno is a small microcontroller that can process electrical input from sensors and control actuators and lights. This capability makes the Arduino Uno an ideal starting point for physical computing projects and for measurement systems that require I²C or SPI communication. The Raspberry Pi is a small, inexpensive mini-computer and is often used for projects that need to be connected to the internet or require more computational power. The ITLL Pi package includes a camera so that students can experiment with the Raspberry Pi vision processing capabilities.

From strain gauges to humidity sensors, the ITLL has hundreds of sensors available for student use. Students can check out sensors for temperature, force, acceleration, vibration, sound, infrared, UV, humidity and more !

While some handheld sensors have integrated data acquisition systems for quick and simple measurements, most of the sensors require the use of external data acquisition equipment (often an Arduino Uno or a National Instruments data acquisition module).

Typical checkout time is 2 days to 2 weeks depending on the sensor.

Soldering

The ITLL Electronics Center is outfitted with equipment and hand tools for through-hole and surface mount device soldering and rework. The Electronics Center offers skill building workshops for through-hole and surface mount device soldering. It offers instruction on the best practices for soldering and desoldering as well as circuit board repair.

Wood Shop

The ITLL Manufacturing Center’s wood shop is equipped with the most common woodworking machines and tools for your basic course-related project needs.

All students must complete our Saws, Drills and Construction Techniques and Tips workshop to use the equipment independently and unsupervised.

The workshop covers the machines controls and adjustments. Safe operating techniques and blade changing. Also, discussions regarding measuring methods, fastener selection, as well as tips and tricks for construction and pitfall avoidance.

Metal Shop

The Metal Shop provides students with access to cutting-edge computer numerically controlled machines, manual machines, and fabrication resources for all metal, plastic, and composite projects and components. Students are encouraged to submit machining designs early in the design cycle to ensure adequate time for consultation and assistance. Using the latest Mastercam for Solidworks add-in and workshop resources, students can generate part programs for use on our new three- or five-axis Hurco machining centers.

Material Testing

The ITLL has several instruments designed to test the material properties and structural integrity of student projects. All the material-testing machines are equipped with data acquisition equipment and software. The ITLL has two universal test frames for tensile, compressive and bending tests, two torsion test machines, and a Rockwell hardness tester available for student/staff/faculty use on a reservation basis. In addition, there are three shakers and a vibration table for vibration testing.

Software

The ITLL offers a plethora of engineering and design-related software in the laboratory. All software is installed on all public facing computers in the ITLL, many of which are publicly available. In specific cases a CU or ITLL account may be required for personal licensing. Please refer to the ITLL Software page for specifics on software access.

Laptops

Laptops are available for short-term student checkout and long-term instructor/course assistant checkout to facilitate coursework or for outreach events.

Modules

The value of experiential learning is the cornerstone of the ITL Program and Laboratory. Modular experiments are designed to provide hands-on, real-world enhancements to traditional theory courses. Modular experiments are small-scaled portable experiments mounted on carts that can be checked out and wheeled to a LabStation in a lab plaza. The open-ended elements of these experiments allow for multidisciplinary exploration that cross traditional departmental boundaries.

Video Equipment

Document your engineering project and help advance your own learning as well as others at the ITLL! Cameras, projectors, microphones, and even headphones are available for engineering students and instructors to check out. Our list includes:

- Digital cameras

- Digital video cameras (and accessories such as tripods)

- Microphones

- Sound-level meters

- High-speed cameras

- Thermal cameras

- GoPro cameras

Sewing

Not all engineering is done with metal and plastics. Working with textiles is a fantastic way to bring comfort, aesthetic, and versatility to your projects. With an assortment of basic stitching tools, a pair of hardy Janome DC2015 sewing machines, and even a leatherworking station, the Sewing Nook will give you all you need to integrate textiles into your design. The ITLL also offers sewing workshops to teach you how to use hand needles and sewing machines, and even delves into the realm of “wearable electronics”, which can be stitched into fabrics to create smart fabrics.